1. Powder Spraying Oven Booth Components and Design

A Powder Spraying Oven Booth integrates a spray chamber and curing oven into a single unit, streamlining the coating process. Key components include an insulated curing chamber, electrostatic spray guns, HEPA filters, conveyor systems, and exhaust vents. Advanced models feature multi-zone temperature controls (±2°C accuracy), IoT-enabled diagnostics, and energy-efficient heat recovery systems. The booth’s stainless steel construction ensures durability, while modular designs allow scalability for varying production needs.

2. Applications of Powder Spraying Oven Booths

These systems are essential in automotive manufacturing (car parts, wheels), appliance production (ovens, refrigerators), and architectural metalwork (steel beams). They also serve aerospace (engine components), medical devices (surgical tools), and agricultural machinery. Their ability to combine spraying and curing in one unit saves floor space and boosts efficiency for high-volume operations.

3. Powder Spraying Oven Booth Price Ranges

Basic manual booths start at 20,000,whilesemi−automatedsystemsrangefrom50,000–150,000.FullyautomatedlineswithroboticarmsandAI−drivencontrolsexceed300,000. Pricing factors include booth size (5x5x10 ft to 20x20x40 ft), heating technology (electric, gas, infrared), and energy efficiency features.

4. Best Practices for Operating Powder Spraying Oven Booths

Surface Preparation: Degrease substrates and apply phosphate coatings for adhesion.

Spray Parameters: Set voltage (50–100 kV) and airflow (0.5–1.5 bar) based on part geometry.

Curing: Maintain 180–220°C for 10–25 minutes; monitor with IR sensors.

Maintenance: Clean filters weekly, inspect grounding systems monthly, and recalibrate thermostats quarterly.

5. How to Select a Powder Spraying Oven Booth

Production Volume: Choose batch systems for low output or conveyor-integrated booths for mass production.

Energy Source: Electric ovens for precision; gas models for cost efficiency.

Certifications: Prioritize NFPA 86, CE, and OSHA compliance.

Customization: Opt for modular designs to accommodate future expansion.

6. Safety Protocols for Powder Spraying Oven Booths

Ventilation: Install explosion-proof exhaust systems to mitigate combustible dust risks.

Grounding: Ensure <1 ohm resistance to prevent static discharge.

PPE: Mandate NIOSH-approved respirators, heat-resistant gloves, and safety goggles.

Fire Safety: Equip booths with CO2 suppression systems and thermal cutoffs.

7. Cost-Efficiency of Modern Powder Spraying Oven Booths

Advanced booths reduce energy consumption by 30% via heat recovery and variable-speed fans. IoT integration enables predictive maintenance, cutting downtime by 40%. High overspray recovery rates (95%+) minimize material waste, while durable construction ensures a 10–15 year lifespan.

8. FAQs on Powder Spraying Oven Booths

Q: How does a powder spraying oven booth improve workflow?

A: Combining spraying and curing in one unit reduces transfer time and floor space requirements.

Q: Can these booths handle large or irregular parts?

A: Yes, customizable conveyor systems and adjustable racks accommodate diverse geometries.

Q: What maintenance ensures oven booth longevity?

A: Replace heating elements every 5,000 hours and clean airflow ducts monthly.

Q: Are powder spraying oven booths eco-friendly?

A: Energy-efficient models with zero VOC emissions comply with EPA and REACH standards.

Q: How to verify booth temperature accuracy?

A: Use calibrated thermocouples and perform annual third-party validations.

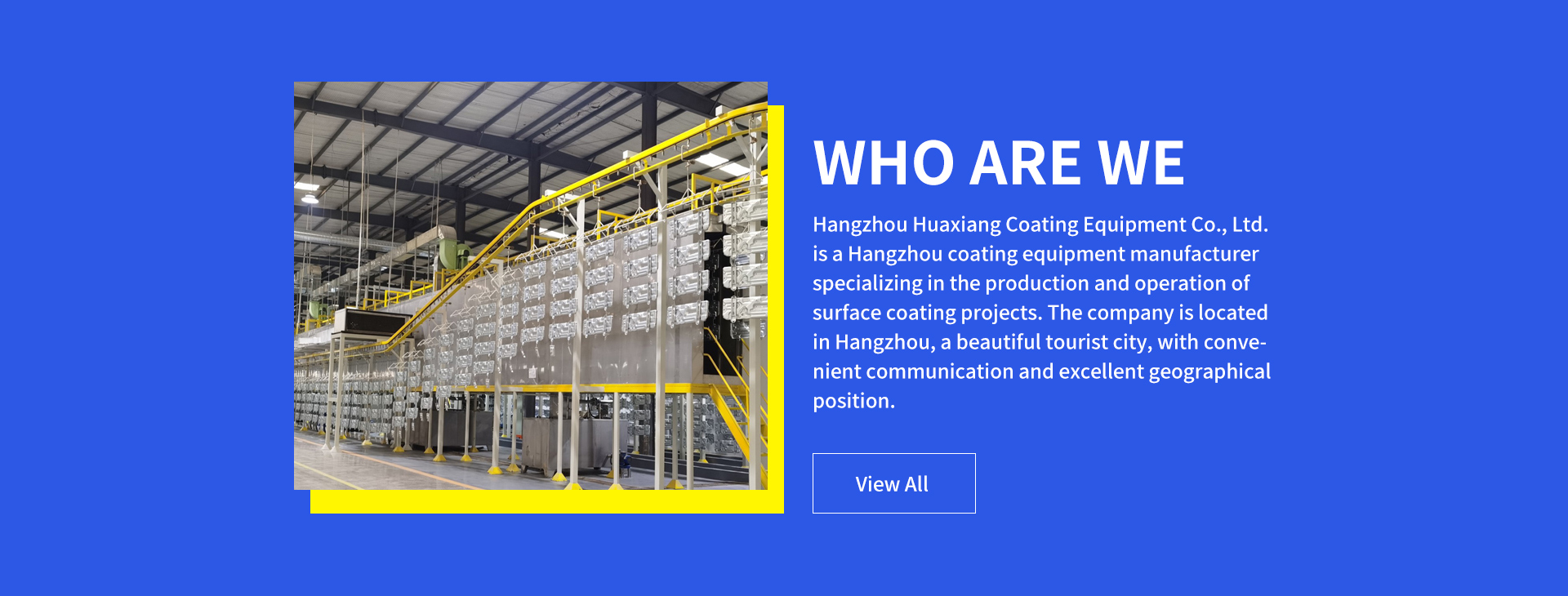

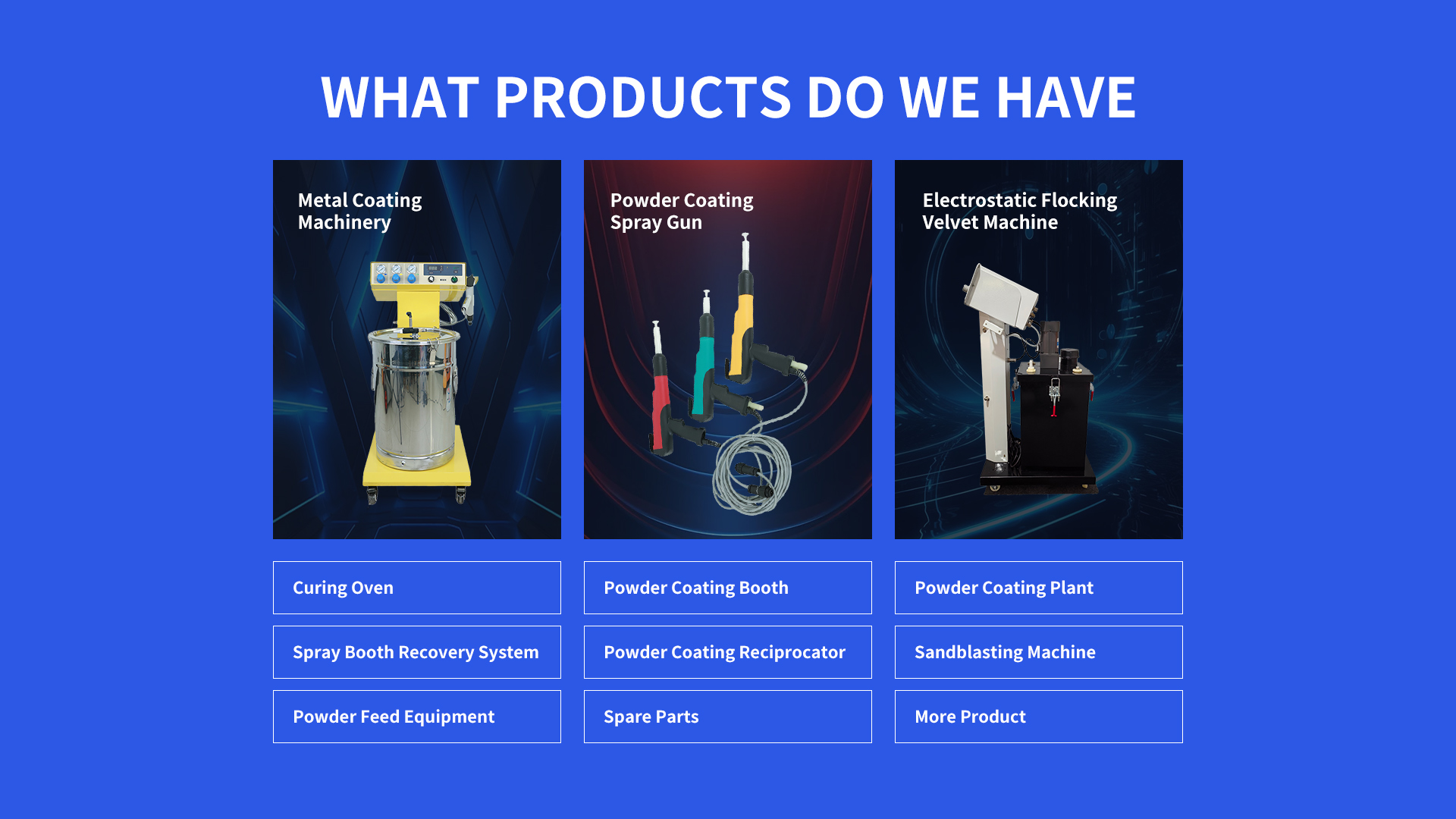

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com